Unlocking the Versatility: Exploring the World of Folding Plastic Box Molds

In the world of packaging and storage, folding plastic boxes have gained immense popularity for their practicality and versatility. These boxes are not only space-efficient but also easy to transport and store when not in use. The secret behind their seamless design lies in the folding plastic box molds, which play a vital role in shaping these versatile containers.

The Magic of Folding Plastic Boxes

Folding plastic boxes are ingenious solutions for packaging, storage, and transportation. Their key features include:

Space Efficiency: Folding plastic boxes can be easily collapsed when empty, significantly reducing the space required for storage and transport.

Durability: These boxes are designed to withstand wear and tear, ensuring that they maintain their structural integrity over time.

Versatility: Folding plastic boxes are used in various industries, including logistics, agriculture, retail, and manufacturing, for applications such as shipping, storage, and display.

Sustainability: They are often made from recyclable materials, making them an eco-friendly choice in comparison to single-use packaging.

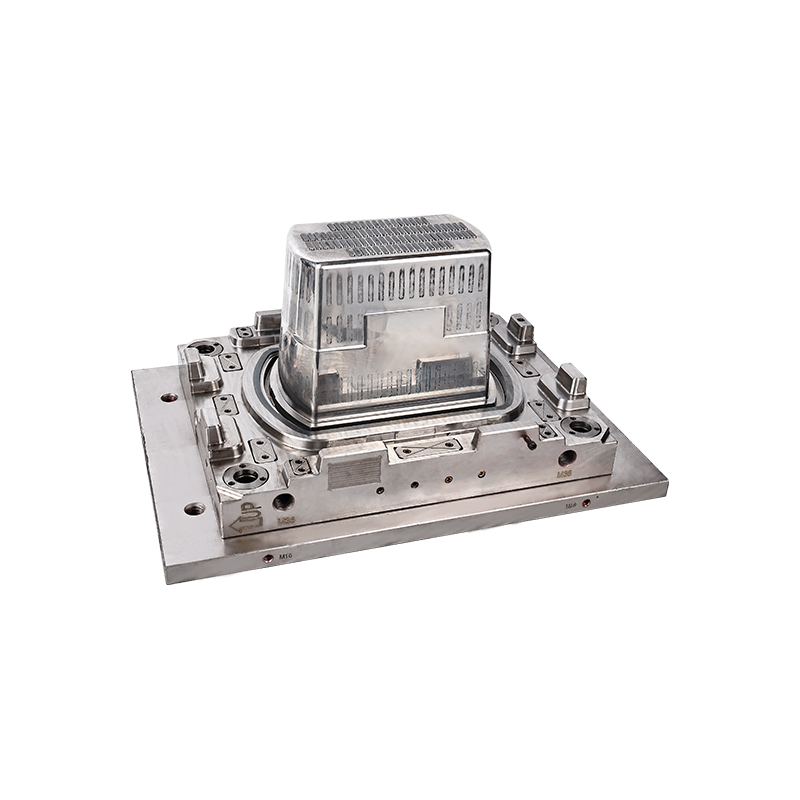

The Role of Folding Plastic Box Molds

Folding plastic box molds are the unsung heroes behind the creation of these versatile containers. These molds are instrumental in determining the shape, size, and features of the folding plastic boxes. They are used in injection molding processes to create the precise form and functionality required for various applications.

Types of Folding Plastic Box Molds

Stackable Folding Plastic Box Molds

Stackable folding plastic box molds are designed to create boxes that can be securely stacked on top of each other. These molds are widely used in logistics and warehousing industries where efficient storage and transportation are essential. Stackable folding plastic boxes are known for their stability and ease of handling when stacked, ensuring that they remain secure during transportation.

Applications: These molds are ideal for products that need to be stacked on pallets or shelves, such as automotive parts, electronics, and pharmaceuticals.

Collapsible Folding Plastic Box Molds

Collapsible folding plastic box molds are engineered to create boxes that can be easily folded down flat when empty. This design is ideal for saving space during return shipments or when the boxes are not in use. Collapsible folding plastic boxes are a preferred choice in industries that require efficient storage and reduced shipping costs.

Applications: These molds are commonly used in the agricultural industry for the transportation of fruits and vegetables. They are also valuable in the e-commerce sector for shipping a wide range of products.

Nestable Folding Plastic Box Molds

Nestable folding plastic box molds are designed to create boxes that can be nested inside each other when empty. This nesting design optimizes storage space, as one box can fit inside another, reducing the overall footprint. Nestable folding plastic boxes are widely used in retail, distribution, and food industries.

Applications: These molds are suitable for applications that require efficient storage and display, such as supermarkets, bakeries, and textile stores.

Ventilated Folding Plastic Box Molds

Ventilated folding plastic box molds are created with perforations or slots in the walls to allow for airflow. These molds are valuable in situations where the contents need ventilation or drainage, such as in the agricultural and food processing industries. Ventilated folding plastic boxes are essential for the transportation and storage of perishable items.

Applications: These molds are often used for storing and transporting fresh produce, seafood, and dairy products.

Hinged Folding Plastic Box Molds

Hinged folding plastic box molds are designed to create boxes with hinged lids or covers. The hinged design provides quick and easy access to the contents, making them a suitable choice for applications where frequent access is required. Hinged folding plastic boxes are used in various industries, including retail, pharmaceuticals, and manufacturing.

Applications: These molds are ideal for storing and transporting small parts, tools, and medical supplies. They are also commonly used in retail stores for displaying jewelry and cosmetics.

Innovations in Folding Plastic Box Mold Design

As technology and materials continue to evolve, innovations in folding plastic box mold design have become increasingly common. Some notable innovations include:

Improved Durability: Modern molds are constructed using high-quality materials that enhance the durability and lifespan of folding plastic boxes, ensuring they can withstand challenging environments and heavy use.

Customization: Advanced mold design allows for greater customization, enabling manufacturers to create folding plastic boxes tailored to specific industry needs. This includes the ability to add logos, labels, or additional features like dividers and compartments.

Sustainability: Many folding plastic box molds are now designed with sustainability in mind. They use recyclable materials and are constructed to minimize waste during the manufacturing process, aligning with the growing demand for eco-friendly packaging solutions.

Ergonomics: Innovations in mold design focus on improving the ergonomics of folding plastic boxes. This includes features like comfortable handles, smooth-opening hinged lids, and secure stacking mechanisms.

English

English  русский

русский Español

Español