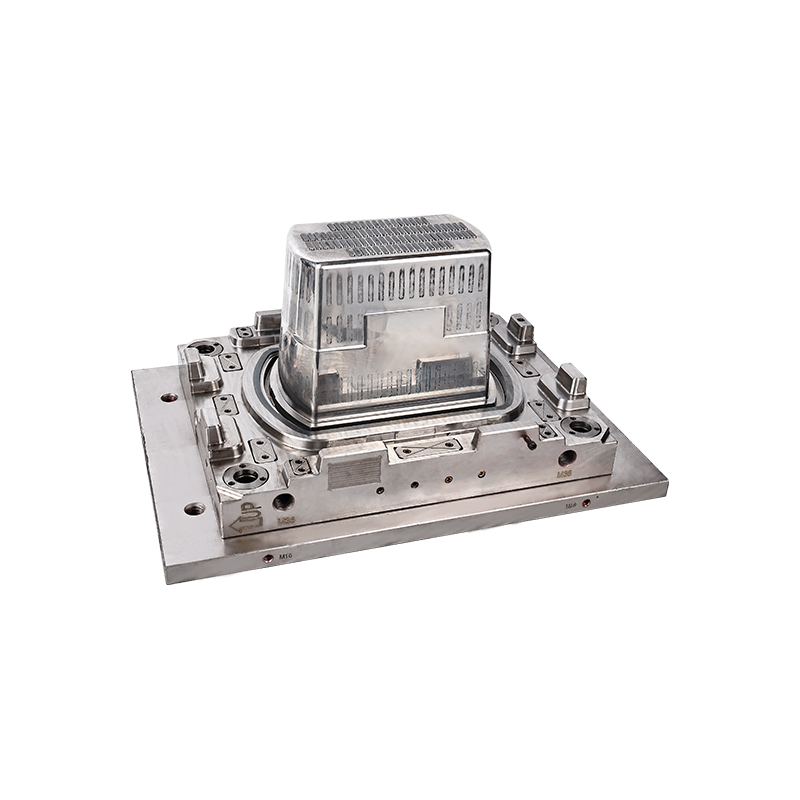

The Material and Introduction of Plastic Sealed Paint Bucket Molds

In the realm of industrial design and manufacturing, innovation is a driving force that continually reshapes the landscape. One such innovation is the plastic sealed paint bucket mold, a solution that combines practicality and efficiency for storing and distributing paints and coatings.

Paints and coatings are essential for enhancing the appearance and protection of various surfaces. The plastic sealed paint bucket molds introduced a new level of convenience by offering airtight and leak-proof containers for these products. These molds allow manufacturers to produce sealed paint buckets that prevent spillage, preserve the quality of the contents, and simplify transportation and storage.

Materials:

The choice of materials for plastic sealed paint bucket molds is critical to ensuring the longevity, precision, and reliability of the final product. High-quality molds are crafted from durable and temperature-resistant materials that withstand the stresses of the molding process and produce consistent results.

1. Stainless Steel:

Stainless steel is a preferred material for crafting plastic sealed paint bucket molds due to its exceptional durability and precision. It can withstand the high pressures and temperatures of the injection molding process without warping or deforming. Stainless steel molds provide consistent results, ensuring that each paint bucket maintains the desired shape and functionality.

2. Aluminum:

Aluminum molds are another option commonly used in plastic sealed paint bucket manufacturing. Aluminum offers excellent heat conductivity, allowing for faster cooling times during the molding process. This can lead to increased productivity and shorter cycle times. Additionally, aluminum molds are lighter than stainless steel molds, making them easier to handle and transport.

3. Mold Inserts:

In some cases, plastic sealed paint bucket molds incorporate specialized mold inserts made from materials like P20 steel or hardened tool steel. These inserts are used to create intricate details, such as branding or logos, on the surface of the paint buckets. Inserts are carefully crafted to ensure precise placement and consistent results.

4. Surface Coatings:

To further enhance the durability and longevity of plastic sealed paint bucket molds, manufacturers often apply surface coatings. These coatings provide protection against wear, corrosion, and chemical reactions caused by the molding process and the materials used. Coated molds maintain their performance over extended production cycles.

Benefits of Plastic Sealed Paint Bucket Molds:

Quality Assurance: Plastic sealed paint bucket molds ensure consistent quality in the final product. The molds' precision and durability contribute to the paint buckets' structural integrity and airtight sealing, preventing leaks and preserving the contents.

Efficiency: The use of advanced materials and efficient molding processes results in streamlined production. Shorter cycle times and minimal maintenance contribute to increased productivity and reduced operational costs.

Customization: Plastic sealed paint bucket molds can be customized to accommodate various sizes, shapes, and features. This flexibility allows manufacturers to cater to specific customer needs and design preferences.

Environmental Considerations: Plastic sealed paint bucket molds align with sustainable practices by ensuring that paint and coating products remain sealed and intact. This prevents wastage due to spillage or contamination.

The introduction of plastic-sealed paint bucket molds has reshaped the way paints and coatings are packaged and distributed.As industries continue to evolve, these molds stand as a testament to the innovative spirit that drives progress and enhances everyday processes. The next time you open a sealed paint bucket, consider the intricate design and craftsmanship that went into creating this seemingly simple yet highly effective solution.

English

English  русский

русский Español

Español