The Impact of Pallet Mould in Logistics and Warehousing

Pallet mould has emerged as a transformative force in the field of material handling, revolutionizing the logistics and warehousing industry. Pallet Mould has solidified its significance as a crucial component in the production of high-quality and durable pallets, offering enhanced efficiency, cost-effectiveness, and sustainability.

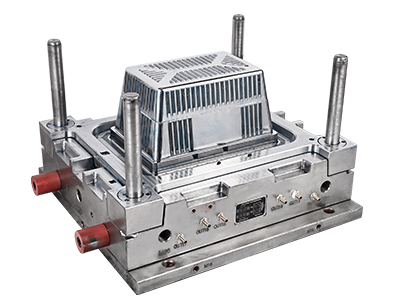

Pallets play a vital role in the transportation and storage of goods, providing a sturdy and standardized platform for handling materials. Pallet moulds are meticulously designed and crafted with precision, using advanced materials such as steel or plastic, to create pallets that can withstand heavy loads and rigorous handling. The dimensional accuracy and durability of Pallet moulds ensure the production of pallets that meet industry standards, optimizing the logistics process.

One of the primary advantages of pallet moulds lies in their ability to produce consistent and uniform pallets. The molds are engineered to replicate the desired specifications and dimensions, ensuring compatibility with automated material handling systems and optimizing space utilization in warehouses and transportation vehicles. The precision of pallet moulds guarantees the seamless stacking, storage, and movement of goods, streamlining the logistics workflow.

Furthermore, pallet moulds offer manufacturers the flexibility to cater to diverse industry requirements. These molds can be customized to produce pallets of varying sizes, designs, and load capacities, tailored to meet specific operational needs. Whether it's for pharmaceuticals, food and beverage, retail, or manufacturing sectors, Pallet moulds enable the production of pallets that align with the unique demands of different industries, ensuring efficient and secure material handling.

The durability and longevity of pallet moulds contribute to the overall reliability of pallets. These molds undergo rigorous testing and quality control measures to ensure the strength and structural integrity of the produced pallets. The robust construction of pallet moulds enables them to withstand the demanding conditions of material handling, including heavy loads, impacts, and temperature variations. The longevity of the pallets produced using Pallet moulds reduces replacement costs and enhances operational efficiency.

In addition to their technical prowess, pallet moulds play a pivotal role in promoting sustainability in the logistics industry. The molds facilitate the production of eco-friendly pallets made from recycled or recyclable materials. These sustainable pallets help reduce environmental impact, minimize waste, and contribute to a greener supply chain. Pallet moulds enable manufacturers to embrace sustainable practices without compromising on the performance and durability of the pallets.

Moreover, pallet moulds enhance productivity and cost-effectiveness in material handling operations. The molds enable high-speed and automated production processes, reducing manufacturing time and labor costs. Pallets produced using Pallet moulds are lightweight yet robust, allowing for efficient handling, stacking, and transportation of goods. The efficient use of space, ease of handling, and compatibility with automated systems contribute to streamlined operations and improved productivity in warehouses and distribution centers.

The market demand for pallet moulds continues to grow as the logistics industry evolves. These molds have become an indispensable tool for manufacturers and logistics providers, enabling them to meet the increasing demands of efficient material handling. The ongoing advancements in Pallet Mould technology, such as the integration of smart features and enhanced design capabilities, further drive the industry towards improved efficiency, safety, and sustainability.

English

English  русский

русский Español

Español