Innovation and Efficiency: How Basket Mold Factories Drive Industry Growth

Basket Mold Factory Maker Wholesaler in China Manufacturing

In the realm of manufacturing, innovation, and efficiency are essential drivers of industry growth and success. Basket mold factories, equipped with advanced technology and skilled artisans, play a pivotal role in driving innovation, improving productivity, and fueling the growth of various industries. From food packaging to automotive components, basket mold factories leverage cutting-edge techniques and expertise to deliver high-quality molds that meet the evolving needs of customers and markets.

The Role of Basket Mold Factories:

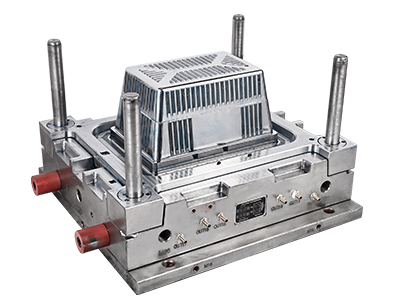

Basket mold factories serve as the backbone of many manufacturing sectors, providing essential tools for producing plastic or metal baskets used in a wide range of applications. These factories are equipped with state-of-the-art machinery, experienced engineers, and skilled craftsmen who work collaboratively to design, fabricate, and optimize basket molds for diverse customer requirements. Whether it's creating prototypes, refining designs, or scaling up production, basket mold factories play a crucial role in bringing innovative solutions to market.

Advancements in Mold Design and Engineering:

In recent years, basket mold factories have witnessed significant advancements in mold design and engineering, driven by technological innovation and industry demands. Computer-aided design (CAD) software allows engineers to create intricate mold designs with precision and efficiency, optimizing factors such as part geometry, material flow, and cooling systems. Advanced simulation tools simulate the injection molding process, enabling engineers to identify potential issues and optimize mold designs before production begins. These advancements in mold design and engineering contribute to improved part quality, reduced cycle times, and enhanced productivity, driving industry growth and competitiveness.

Customization and Flexibility:

One of the key strengths of basket mold factories is their ability to offer customization and flexibility to customers. From modifying existing designs to creating entirely new molds from scratch, these factories work closely with customers to understand their unique requirements and deliver tailored solutions. Customization options include adjusting mold cavity sizes, incorporating specific features, and optimizing cooling systems to achieve optimal part quality and performance. By offering customizable solutions, basket mold factories enable customers to innovate and differentiate their products in the market, driving growth and success.

Integration of Advanced Manufacturing Technologies:

Basket mold factories leverage advanced manufacturing technologies to optimize production processes and enhance efficiency. High-precision CNC machining centers, electrical discharge machining (EDM) machines, and computer numerical control (CNC) wire-cutting machines are used to fabricate mold components with unparalleled accuracy and consistency. Automation and robotics are increasingly integrated into manufacturing processes to streamline production, reduce labor costs, and improve throughput. These advancements in manufacturing technologies enable basket mold factories to meet the growing demand for high-quality molds with greater speed and efficiency, driving industry growth and competitiveness.

Sustainable and Eco-Friendly Practices:

In response to growing environmental concerns, basket mold factories are adopting sustainable and eco-friendly practices to minimize their environmental footprint. This includes optimizing manufacturing processes to reduce waste, recycling scrap materials, and implementing energy-efficient technologies. Additionally, there is a growing trend towards using biodegradable and recyclable materials in mold fabrication, reducing reliance on traditional plastics and promoting environmental sustainability. By embracing sustainable practices, basket mold factories contribute to a more sustainable future while driving industry growth and innovation.

Collaboration and Partnerships:

Collaboration and partnerships play a crucial role in driving industry growth and innovation. Basket mold factories often collaborate with customers, suppliers, and research institutions to exchange knowledge, share resources, and develop new technologies. By working together, stakeholders can leverage their collective expertise and resources to address industry challenges, explore new opportunities, and drive innovation. Collaborative partnerships facilitate the co-development of innovative solutions that meet the evolving needs of customers and markets, driving industry growth and competitiveness.

Basket mold factories are at the forefront of driving industry growth through innovation and efficiency. Advancements in mold design and engineering, integration of advanced manufacturing technologies, and collaboration with stakeholders contribute to improved productivity, enhanced competitiveness, and sustainable growth across various industries. As basket mold factories continue to innovate and evolve, they will play an increasingly vital role in driving industry growth and shaping the future of manufacturing.

English

English  русский

русский Español

Español